- — 12 months warranty

- — SMS notification

- — Return and exchange

- — Different payment methods

- — Best price

Ultra Clear Epoxy Bar Top, Tabletop, & Countertop Epoxy for Restaurants and Homes (COMMERCIAL GRADE)

Works on:

- Wood

- Concrete

- Granite

- Copper

- Stainless Steel

- Laminate

- Cork

- Formica

- Quartz

- Corian

- Bamboo

- Bottle Caps

- Pennies

- Tile

- Stickers

- Labels

- Photos and Painted Surfaces.

Ultra Clear Bar and Table Top Epoxy is a specially formulated commercial epoxy resin that is used in restaurants, hotels, casinos, bars, pubs, and night clubs around the world. Ultra Clear Epoxy can be used for Bar Tops, Tabletops, & Countertops.

Crystal Clear Epoxy

Unlike most epoxy resins, our unique blend of polycarbons produces a completely transparent finish that will never yellow, fade, or crack with time. It's a product you can trust!

Extremely Durable & Self-Leveling

Ultra Clear Epoxy self-levels to 1/8", creating a virtually indestructible surface. Most epoxies only coat 1/16" requiring multiple coats. UltraClear coats at 1/8". That's over 2 times as thick! The result is a crystal clear, brilliant surface that accentuates the material below it. Truly beautiful to behold!

Scratch Resilient & Maintenance Free

Ultra Clear Epoxy is specially formulated to resist scratching and provide long lasting maintenance free protection for your surface.

100% VOC Free

Ultra Clear Epoxy is free from volatile organic compounds and is compliant with all environmental requirements implemented by international organizations such as the Environmental Protection Agency and the World Health Organization.

How It Works UltraClear Epoxy is a two-part, clear polymer coating that is mixed at a 1 to 1 ratio.

1. Pour an equal amount of hardener and resin into a container.

2. Mix thoroughly with our mixing drill bit.

3. Pour epoxy onto your surface.

Application

For wood surfaces, we recommend applying a seal coat of epoxy (same material, just a smaller painted on coat) before pouring the self-level coat. The seal coat is brushed on in a thin layer and is used to seal any pores in the surface and prevent air bubbles from forming in the following flood coat. This stage is followed by the flood coat, which will flow and self level to 1/8". The flood coat should be poured approximately 4-6 hours after the seal coat. Do not exceed 6 hours. Flood coats are applied in 1/8" layers at a time, as many as desired can be applied, however one coat is average for restaurant tables, bar tops, and countertops. Additional coats are used to cover any items, such as memorabilia where you need to build up the epoxy to cover them adequately.

Embedding Pictures

Objects, such as pictures, maps, etc. can be embedded in this product during the pouring process. Most photo quality paper does not require any special preparation; however, sometimes thin paper objects must first be sealed with Elmer's glue or a similar product to prevent the epoxy from fully penetrating the paper and causing it to become transparent.

Embedding Solid Objects (pennies, rocks, corks, shells, bottle caps...)

Glue down items with Elmer's glue. All porous materials should first have a seal coat of epoxy applied. This will prevent air bubbles from occurring in subsequent flood coats.

Exterior Applications

Please note that although this product will resist yellowing better than other epoxies, it is NOT 100% UV resistant. Continuous outdoor UV exposure over months or years will cause the finish to lose its gloss and cause gradual changes in color..

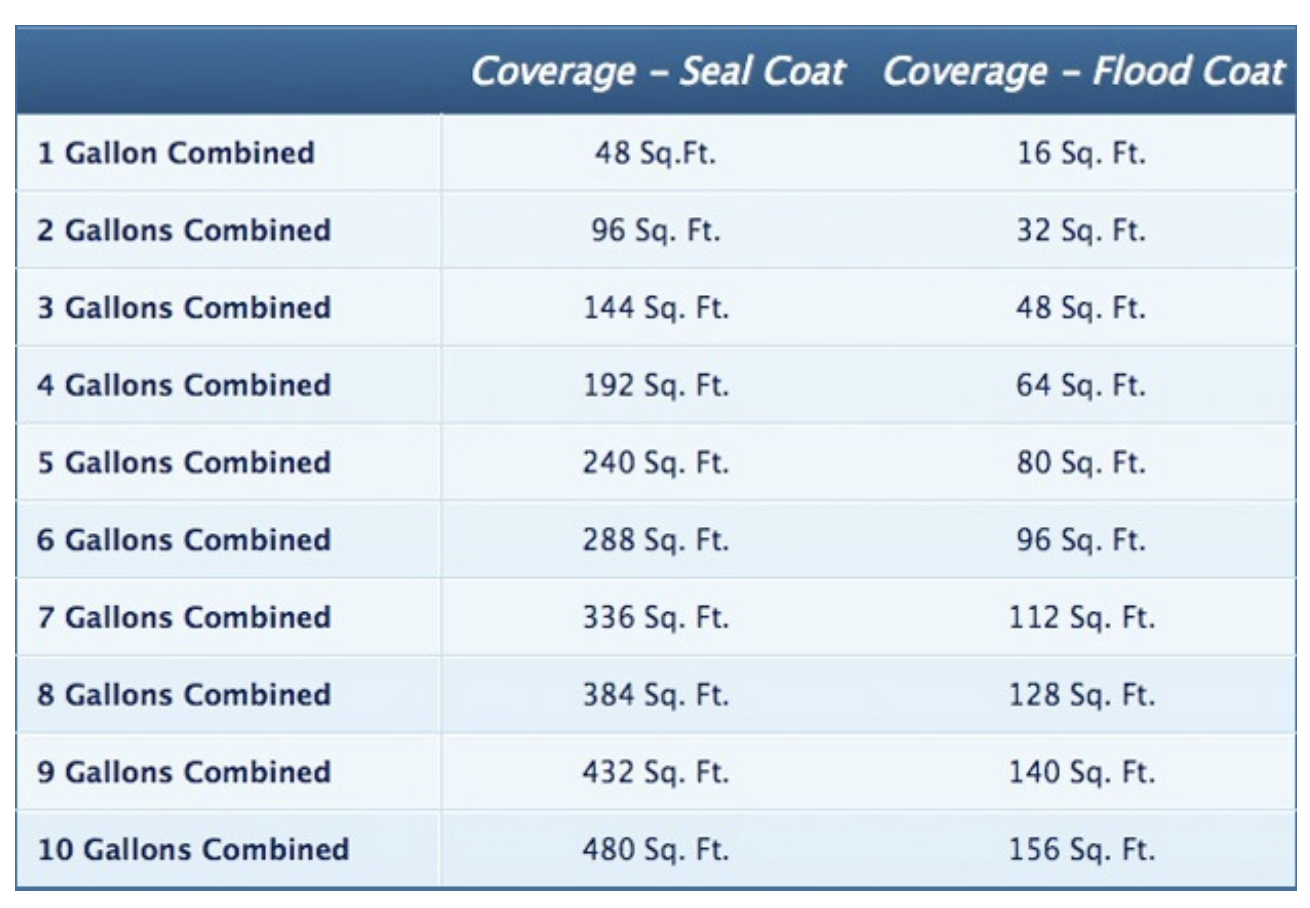

Coverage: See the coverage charts shown below to calculate the amount you will need for your area.

Working Temperature of Product:

The working room temperature must be above 75 degrees, several hours prior to mixing the epoxy. We recommend that the product be brought inside and acclimated to room temperature, as it will be cold during winter shipping months. Use space heaters if necessary to ensure the temperature remains above 75 degrees in cold areas, such as garages and basements. It is extremely important that the temperature remain above 75 degrees for a full 72 hours, in order for the epoxy to cure. High or low humidity and higher temperatures (75-110 degrees) are perfectly fine for curing; the epoxy cures much faster with higher temperatures.

No reviews found